Have you ever wanted to get a shoe prototype made? If so, then this article is for you. In this article, we will discuss how to get a shoe prototype made and what to expect in each step of the process. We will also discuss some precautions that you need to consider before you move further on these steps.

Steps To Follow on How to Get a Shoe Prototype Made

We have included Six key steps that all need to be completed before your shoes can be prototyped.

Step 1: Get Creative:

The first step is to get creative and think about what type of shoe you want. This includes a style, color, material, heel height or shape, etc. Then, create a design and mockup that you are happy with. You can find templates to create your own in many online tutorials or on Google.

Step 2: Choose Materials:

Next, you will need to decide what materials are best for your design. Some common materials are leather or fabric, which require additional steps before prototyping. If in doubt, start with leather or canvas and go from there. You will also need to decide what size and style you want.

Step 3: Find a Manufacturer:

Now, it’s time to find a manufacturer. Again, it is important that you know your design well and has an idea of what materials will work best so they can give you the proper information for sourcing those materials.

You should also know the type and level of quality you would like your shoes to be made with; this will help narrow down who might make it for you. You’ll also want to get as many quotes from manufacturers as possible before deciding on who to go with – this way, you will be able to compare prices and quality.

Step 4: Hire an Engineer (optional):

If you want a more complex shoe, or need to build your own tooling, it is worth hiring an engineer. When looking for engineers, make sure that they have experience with the material and design of your shoes.

Step 5: Inspect Prototype:

This is usually the point at which you get to see your shoe design come to life. Make sure that no small details or features are missing from the prototype and that it’s created with high-quality materials. This will also be a good time for feedback on how comfortable the shoes feel and any other comments about what could make them better.

Step 6: Order Shoe Samples:

After approving your final prototype, you’ll want to order samples so you can test out different colors or material combinations before deciding on anything further. Of course, it doesn’t hurt if they cost more than ordering just one pair. This way, you can have options available when making decisions later down the line!

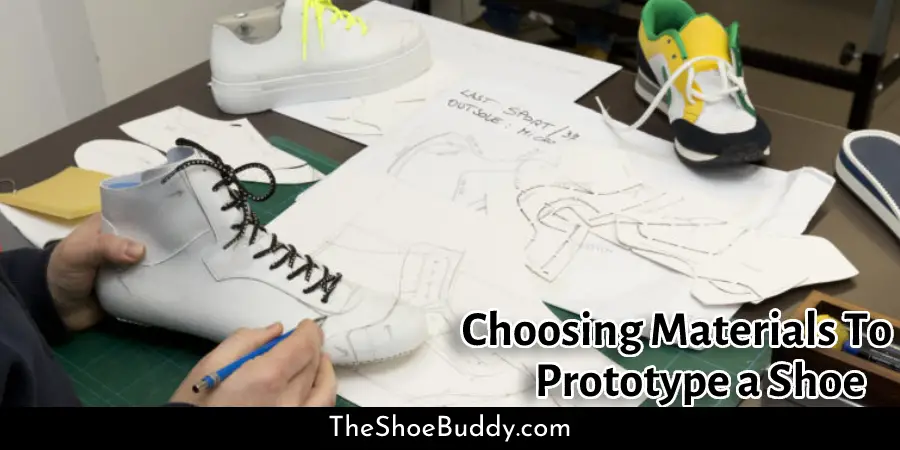

Choosing Materials To Prototype a Shoe

Choosing the right materials to prototype a shoe is critical. You need tough and durable material that can withstand wear from being walked on, hitting with a hammer, or even thrown onto concrete. So we have given some advice below on choosing materials for prototyping:

- To get an idea of what your final product will be like before investing in manufacturing costs and labor, you should try making prototypes as close to your final product as possible.

- One way around the costs is to use a material like plaster, which can be ordered from any arts and crafts store in large quantities for cheap.

- Choose one or two representative shoe parts to create in your prototype: top of the heel (shank), midsole pattern, sole pattern, upper pattern, etc.

- For the plaster prototype, you need to know how many layers of material will be needed for your intended shoe part and choose a close thickness to what you want in production shoes.

Things To Consider Before Prototyping Shoe

A prototype is typically a physical representation of an idea. While it may not be the finished product, it could still provide valuable information about proceeding with your project or design process. How do you know if prototyping is right for you? Consider the following:

- You want to test several different options.

- The size and shape of your product might change over time.

- You need to be sure what materials will work best in certain conditions (e.g., temperature)

- Your production methods cannot guarantee quality standards at this stage in the development process.

- You need to test out ergonomics and user experience

Frequently Asked Questions

What materials are used To Prototype a Shoe?

The two common materials used in shoe prototypes are plastic and foam rubber, but you can also use paper or wood to get the idea across. Wood is a good option for prototyping shoes with a lot of shaping because it doesn’t warp under heat as other materials do. Paper is inexpensive, easy to cut, and easy to work with.

Frequently Asked Questions

What Is a Shoe Prototype?

A shoe prototype is a model of a shoe that has been created to demonstrate the design and features of the shoe. It is used to communicate the design and intended use of the product to potential investors, customers, or partners.

There are many benefits associated with prototyping, including:

- Rapid prototyping allows you to create something quickly and accurately to present it to your audience.

- Providing an opportunity for feedback from others on how they would like your product to be designed or function.

- Providing an opportunity for testing before manufacturing begins so that there are no surprises when production starts.

Where Can I Study Shoe Design?

It is important to know that shoe design is a relatively new field. So, where can you study this? You can find out more about this by reading a book or taking an online course. You could also join the International Shoe Design Association, which has information on their website.

What Does a Prototype Do?

A prototype is a simple representation of an idea, product, or process. It is often used to test out the feasibility of an idea or invention before fully developing it.

Prototypes are also important for marketing and advertising purposes because they allow people to understand how something will work without investing in production costs.

What Qualifications Do You Need to Be a Shoe Designer?

Shoe designers need to have a high level of creativity and design sense. They also need to be able to imagine the shoe in their head before it is actually made.

Is Shoe Designer a Career?

Shoe designer is a career that many people are following. The first step to becoming a shoe designer is taking classes in fashion design and learning about the skills needed for this job.

The second step would be starting an apprenticeship with a company where you can learn the basics of how to create shoes.

After gaining experience, you can start working on your own and making trendy and attractive shoes for people who want to wear them.

Conclusion

If you want to learn how to get a shoe prototype made, this is the place for you. In this post, We have talked about what materials are needed for shoe prototyping and where to go in order to make it happen! It’s not too difficult if you know what steps to take.

After reading our blog post, I hope that you will have learned some new things on the matter of getting your own shoe prototype created from scratch.