Introduction

These shoes are basically like normal shoes, except that their material is derived from a plant known as hemp. Hemp comes in many forms, and one of those forms is fabric. The fabric that makes into shoes is called Hemp fiber, and this term should not be confused with other plants which contain THC (the psychoactive ingredient). Many people use this material because it’s very durable and soft to touch or wear on your feet as well. Today I am going to discuss a technique on how to make hemp shoes.

Why Use Hemp for Making Shoes?

Hemp’s properties are extremely suitable for producing shoes and allow us to make unique products that satisfy the person who wears them. Hemp creates a completely natural product using no chemicals or toxic substances, and it is easy to recycle. The materials used in hemp shoes are biodegradable; all of its parts can be reused. In addition, the use of hemp as raw material makes it possible to develop new products, create jobs, and stimulate local economies such as agriculture. These shoes are environmentally friendly, viable, fair, and just.

A Process on How to Make Hemp Shoes

Step 1: Materials You’ll Need

- Hemp fabric – 10mm thick or more (for the inner sole) and 20mm-25mm thick (for the outer sole)

- Leather for the upper part of your shoe

- Soft cotton fabric for lining

- Lining fabric

- White rubber sheet

- Plastic heel (with no metal fixtures)

- Thread

- Hooks

- Strap buckle

- Felt material

- Piping cord

- Buttons

- Fabric glue

- Pins

- Machine needles

- Fabric shears

- A pair of shoes lasts

- Scissors

- Sewing machine

- Hand sewing needle

- Sewing scissors

- Tape measure

- Calculator

- Leather gloves

Step 2: Choosing the Shoe Lasts

The shoe lasts the forms which will be used to mold your shoes. They must be of high quality and durable, as they’ll also serve as a basis for the design of your hemp shoes. You can choose either wooden, or plastic lasts depending on what you like better. If you choose plastic lasts, make sure that these last have holes on their sides so that you can easily take measurements from them. Likewise, if you prefer wood lasts, ensure that these are in good shape – not too porous or cracked because they’ll easily break during manufacture. Warm up your last by putting them inside a dryer for about 5 minutes before using them in making your hemp shoes.

Step 3: First Step-Making the Inner Sole

Tear off two pieces of your hemp fabric and stack them one on top of another. Now sew a seam about 1mm away from their edges so that you can turn these two pieces into four layers. Start by turning in one end and then the other, as shown in the picture below:

Now lay this “fat” strip along with its rough side upwards on your last while pressing it flat onto every curve of the last shape. The inner sole will ultimately be placed against the shoe upper’s an inside area to provide comfort and cushioning for your feet during walking or standing long hours at work. Measure from the heel to around 5cm away from your toes, then draw the line at an angle so you can cut straight to the middle of this area. Fold this “fat strip” into three layers and then place it around the last’s heel, as shown in step 4 below:

Step 4: Making Your Shoe Upper

Using your plastic heels, trace their shapes onto the leather or suede, which will be used for the upper part of your hemp shoes. You may adjust its shape properly and draw lines on your material if you want to use a piping cord when sewing it on with all other materials needed. The picture below shows how you can prepare yourself before making any cuts by drawing seam allowance lines onto your leather or suede fabric:

Now take out your machine needles and put them inside the needle threader. Follow the sample machine sewing steps below to sew your upper leather material with all other materials needed:

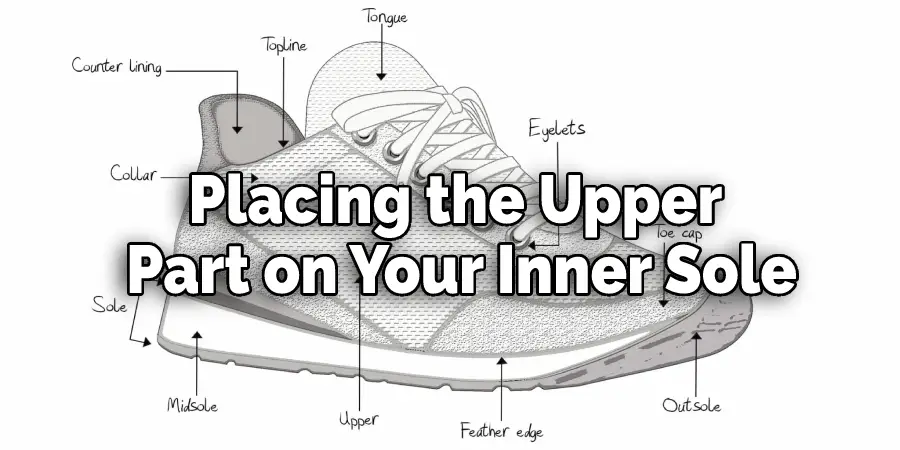

Step 5: Placing the Upper Part on Your Inner Sole

Using a fastener hook, place one side of your strap buckle through its hole and then put this buckle hook into the last’s inner edge where it has been cut off earlier (seen in step 2 above). Now bring another fastener hook to be sewn onto that same edge, as seen in the picture below:

Now get yourself ready for sewing by tying up your usual threading process directly onto the footplate. Stitch while pressing down firmly to avoid any loose threads from forming. To maintain a uniform appearance, make sure you only sew around three-quarters of your shoe upper part and leave the fourth quarter of your last empty. This will later serve as your hemp shoes’ tongue. Next, turn in the strap buckle’s holes so that these buckles can be hidden on both lower edges of your inner soul, seen in the picture below:

Now you’re all set, to begin with, hand sewing! First, look at the photo below to see how you can start stitching from any edge that suits you best before finally meeting up with your previous seam line just after crossing over this seam allowance line:

Step 6: Now its Time for Hand Sewing

As seen in the photo above, pin down and sew through three layers of leather fabric using a hand sewing needle before tying off each stitch individually. It is important to make sure none of the stitches are left unattended for long to prevent unwanted frays.

Step 7: Machine Sewing

Now that you’ve completed the sewing of your upper material and inner sole, time to add on more layers! Attach your dark brown suede layer onto both earlier parts using a machine sewing technique as shown below:

Now get yourself ready to sew through three or four layers at once before moving on to other corners. Ensure that all layers have been thoroughly creased and turned in properly so that no one can see any open edges when viewing from afar. The last required step is putting on your shoe soles. Spread this white cotton cloth onto an older pair of leather shoes, then trace its shape to use it as a template when cutting out your soles. Finally, cut and sew this piece of leather using the same techniques used before.

Step 8: Finishing Touches & Securing Your Hemp Shoes

Take both completed shoe pairs outside by tying them together with either a belt or rope, then dip your hemp shoes to wade through water which is about 10cm high. Take them out when you see bubbles forming in their interior area while squeezing these shoes tightly inside a cloth sack to drain its excess water. Now hang your shoes on the ceiling fan for relaxation!

For durability purposes, if ever you want to make your hemp shoes last longer than usual, spray all surfaces with one or two layers of varnish using an old sponge and brush before drying it out.

Frequently Asked Questions

Can You Make Shoes Out of Hemp?

Yes, you can make shoes out of hemp. Hemp is a type of cannabis plant that has been used for thousands of years to make rope, paper, textiles, and even food products.

It was traditionally grown for the production of rope and fabric, but it can also be grown for the extraction of cannabidiol (CBD) which is an active compound in cannabis plants that has many medical benefits like relieving pain and inflammation without getting you high.

The best way to grow hemp is by using industrial hemp seeds, as they have stronger roots compared to other types of seeds like marijuana.

What Is Hemp Fabric?

Hemp fabric is a type of fabric made from the hemp plant. It is most commonly used to make clothing, although it can also be used in other areas such as carpets and furniture.

Creating hemp fabric starts with harvesting the hemp stalk, or “bud,” by cutting off the leaves and stems at ground level, then stripping away the leaves and flowers. This can be done mechanically or manually. The stripped stem is soaked in water to remove any residual chemicals that may have been left on it from its previous life as a leaf or flower.

Next, you would need to dry out the bud until it’s about 10% moisture content so that it will stay pliable without breaking down into fibers when processed further. Once dried, you would place it on top of a “card,” which consists of two pieces of material (the card itself and an adhesive) which will bond together after pressing for about 15 minutes to create a single sheet of fiber.

Will Hemp Shoes Stretch?

No, hemp shoes will not stretch. The fibers in hemp are too thin to be stretched, so they are a bit tight when you first put them on, but they’ll loosen up over time.

Can You Waterproof Hemp Shoes?

No, hemp shoes are not waterproof. However, they can be water-resistant by using a coating of silicone or polyurethane.

Hemp is known to be one of the strongest natural fibers globally, and it’s tough enough to wear as a textile without needing any further treatment.

Conclusion

Since hemp is a sustainable and eco-friendly material, you’ll be able to do your part for the environment. In addition, because it’s durable and breathable, you won’t have to worry about wearing uncomfortable shoes with these! So make sure to follow the process properly to obtain the best results. Thank you, and have a good day!

You may read also –